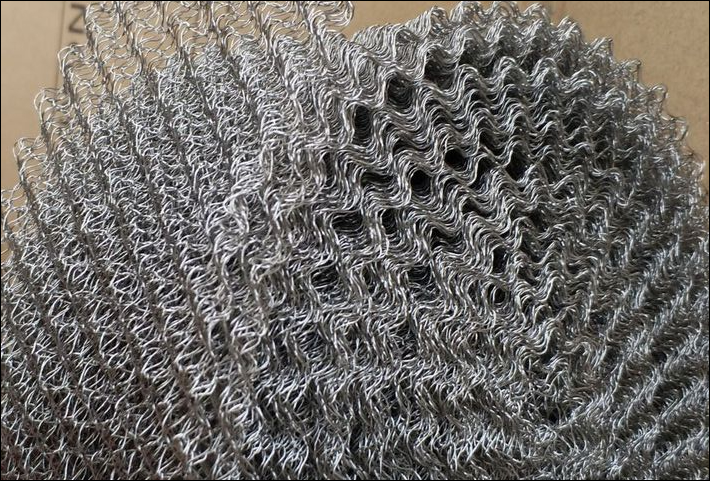

Demister Pads -Demister Knitted Mesh

We supply full range of Demister Pads fabricated in plastic and metal wire knitted mesh materials to suit all kinds of projects applications. Demister Pads are porous mesh blankets designed and constructed to efficiently abate mist particles. All demisters are delivered with Product Conditions of Genuine original, brand new, warranted, certificated ( Manufacturer's standard certificate).

Materials of demister pads and how to choose:

Major materials cover stainless steel, nickel alloy ( monel), aluminum, pp, pe, frp, Teflon, pvc, polyester, and various alloy.

Mist eliminator demister pads shall be chosen based on the operating conditions, such as: gas volume, Temperature, Pressure, droplets/mist to be captured, Type of industry applied.

Metallic Materials Choosing:

The work temperature of non-metallic series varies from PP, PE, PVC, PVDF and ECTFE.

316 ss mesh demister pads can work in a higher temperature environment compared with SS 304.

Aluminum knitted mesh offers a different property compared with stainless steel.

Monel demister is made of nickel-copper alloy with high tensile strength and resistance to corrosion caused by many agressive agents. Suitable for marince uses.

Non-Metal Material Choosing and Work Temperature Standard:

PP: 0°C up to 80°C

PE: - 20°C up to 60°C

PVC: 0°C up to 60°C

PVDF: - 20°C up to 120°C

PVC-C: - 20°C up to 120°C

ECTFE: - 20°C up to 150°C

Demister choosing according to end uses, structures, shapes:

Vane type

Pad with grid

Demister pads in 2 segments, 3 segments, 6 segments, 8 segments and other options.

Square pad, circular pad

Demister pads for knockout drums

Demister pads mufflers, breathers, sleeves, etc.

Demister Mesh Equal to York 431, York 421, York 422, , 326, 333, 371, 483, 241, mist eliminators

York 421 Pad Demister is mainly used in distillation and evaporation of petroleum, chemical, medicine, metallurgy, aerospace, ship, environmental protection.

York 422 Mist Eliminator Demister Pads are made in varied degrees of density with 99.99% Efficiency.

Polypropylene (PP) Wire Mesh Pads Demister

Polypropylene (pp) wire mesh pads demister for sulfuric acid plant

Product Description:

Material style: PP knit fabrics

Dimensions : 30000*2500*20 mm

For temperture up to 100°c

Hardeness : 72 d

Thermal conductivity : 0.22 w/mk

Elongation to break : 70%

Sulfuric Acid Process Flow Diagram

Wire Mesh Data Sheet

The wire mesh of plastic knit

fabrics, available in different structures and

packing heights.

Thickness of wire filament: 0,4 mm

Thickness of mesh pad: 20 mm

Execution:

Dimension and execution according to customer requirements

Overlap between elements 100 mm / to the wall 200 mm, adapted to given situation

Monel Demister Pads

Demister pad, 2 feet wide x 8 feet long x 6 inch thick

Mesh material: monel

York mesh 431

Shape: rectangular

Demister Pads with Grids

Demister 4 coalesce layers, with grids

Pad diameter 948 mm

Thickness 583 mm

Material 316SS knit mesh

Pad structure: Lower Pad in 3 pieces, upper Pad in 4 pieces.

Demister with grids in 3 pieces

Pad diameter 945mm

Thickness 153mm

Material 316SS knit mesh

Demister with grids in 2 pieces

Pad diameter 758mm

Thickness 153mm

Material 316SS knit mesh

Demister with grids in single piece

Pad diameter 435mm

Thickness 150mm

Material 304SS knit mesh

Demister Knitted Mesh ASTM A478 Type 316 ( for Europe, USA, UK)

Corrugated wire diameter: 0.280mm

Form of

supply: Rectangular pad

Pad size: 2000 mm * 500 mm * 100 mm .

Density 150 KG / M3

Material: Austenitic stainless

steel ASTM A 478 type 316.

Demister Pad / Mist Eliminators for Knock out Drums

Demister Pad / Mist Eliminator for Sour Gas Knock Out Drum

Demister Pad for Fuel Gas Compressor Suction Knock Out Drum

Knitted Mesh and Wire Mesh for Demister Pads and Filters

Vane mist eliminators & filters

For pressure vessels, filter separators, filter coalescers, strainers, solutions to the oil, gas, power plant, and process industries.

Material: Stainless steel, aluminum.

Information supplied in response to inquiries of our demister pads materials:

a- Country of Origin

b- Port of shipment

c- Delivery period

d- Weight and volume of consignment

e- Technical literature to the attached